Steel teeth in the deep might sound like something from a sci-fi novel, but they’re now part of real-world strategy. Seabed cables carry the internet, global finance, military comms, and more—about 95% of all international data. That’s what makes them so vital. And now, a precision cable-cutting tool developed by China’s CSSRC is putting those fragile lifelines under new scrutiny.

It’s not just a tool. It’s a message: even the ocean floor isn’t off-limits anymore.

Table of Contents

Balance

The cutter, built by China’s Ship Scientific Research Centre (CSSRC), operates at crushing depths—over 13,000 feet. It works with submersibles like Fendouzhe and Haidou, both crewed and autonomous, to locate and reach deep-sea fiber routes. These aren’t soft targets. The cables are armored in steel and polymer to withstand anchors, fishing nets, and quakes.

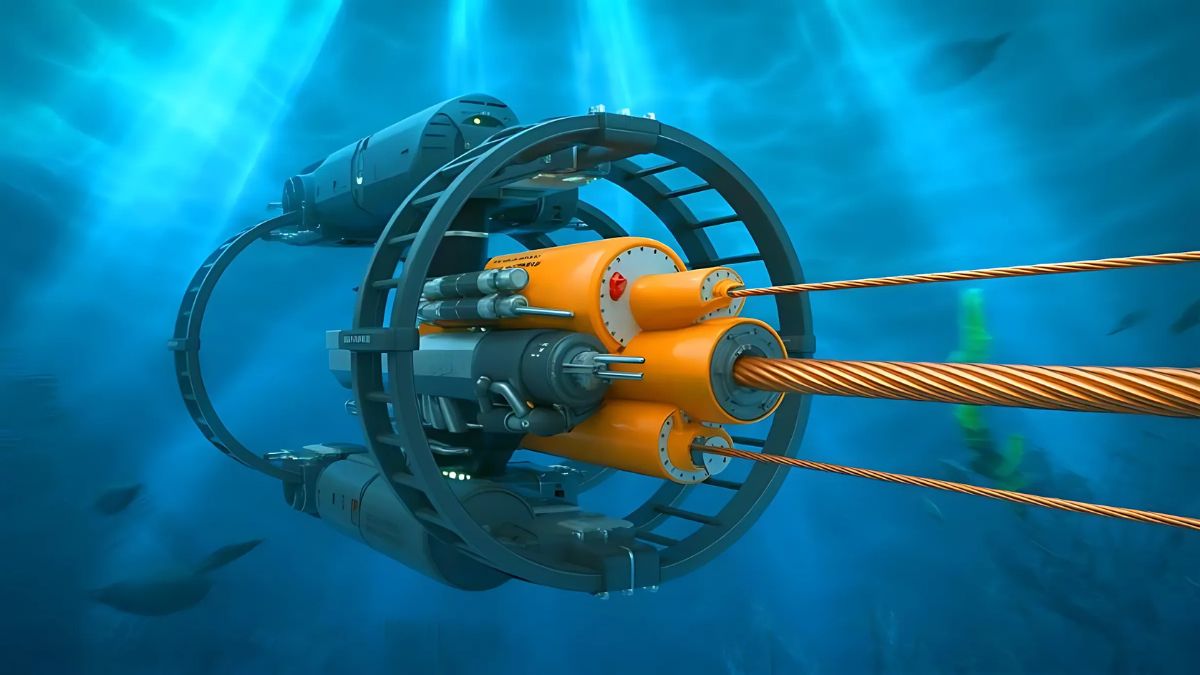

The cutting system uses a diamond-coated grinding wheel spinning at 1,600 rpm. It chews through the armored exterior quietly, with minimal seabed disturbance. Robotic arms help clamp it around the cable like a cast. It doesn’t rip—it slices clean, which allows for repair if needed… or leaves no messy trace if sabotage is the goal.

Engineering

While the official story is about cable repair and seabed mining, the tech raises eyebrows. The tool is precise, quiet, and fast. It’s also incredibly hard to trace if used covertly. That’s why analysts are concerned—it offers plausible deniability. One cut near Guam or Singapore could cause outages without immediate attribution.

Lead engineer Hu Haolong explained the mechanical hurdles. At depth, pressure crushes housings and distorts sensors. A powerful 1-kilowatt motor paired with an 8:1 gear reducer delivers high torque without loss of control. Monitoring heat, pressure, and oil flow is crucial—failure mid-operation is not an option.

The robot relies on acoustic, inertial, and visual guidance to stay stable even in zero visibility and strong underwater currents. Every move is practiced because underwater errors cost time and data—and sometimes spark international incidents.

Dualuse

The cable cutter’s civilian uses are valid. Salvage missions, offshore repairs, and undersea infrastructure projects are real. But the dual-use potential is undeniable. Strategic chokepoints—like those near Japan, the Philippines, or U.S. military hubs—suddenly look more vulnerable.

That’s why defense planners are rethinking cable security. Backup routes, spare cable reels, 24/7 monitoring, and faster response teams are becoming standard. Big cable operators now drill for outages the same way firefighters drill for blazes.

If something happens, you don’t want chaos. You want protocol.

Incidents

This isn’t theoretical anymore. Seabed infrastructure has already seen mysterious damage. Natural gas pipelines, submarine cables, and even scientific sensors have gone offline under murky circumstances. Proving who did it is tough—satellites can’t see that deep, and acoustic data isn’t always clear.

That’s why reporting delays and secrecy hurt response. If one side acts in stealth and the other side panics, escalation follows. Sharing telemetry, logging events, and setting communication channels reduce that risk. But it requires transparency—something still lacking in some regions.

Platforms

China’s advantage lies in its undersea fleet. With more crewed and unmanned submersibles than any other nation, it has the numbers to cover distance and conduct shadow ops. One team scouts, another cuts. Some drop decoys while others do the real work. It’s chess at 13,000 feet.

Reports say the cutter successfully sliced through 2.4-inch-thick cable. That’s industrial strength. Engineers still frame it as marine development support, but the line between peace and pressure keeps getting thinner.

Autonomous platforms are hard to track. They’re quiet, use little light, and only surface when needed. They avoid patrols, wait for storms or diplomatic distractions, then vanish. The strategic value? Huge. The trace? Almost none.

Safeguards

Governments and private operators are scrambling to respond. That includes drills with repair ships, better coordination on permits, and even creating hazard maps. If every country has a response plan, repair time shrinks and chaos is avoided.

Technical fixes include seabed sensors, drone patrols, tamper-evident cable segments, and AI models to detect anomalies. If a cable gets cut, companies can react quickly. Insurance providers are now rewarding those who invest in such systems.

Diplomatically, countries can agree on patrol boundaries, incident reports, and verification methods. Standard formats reduce confusion. The more players know the rules, the less likely they are to panic when something goes wrong.

Outlook

The future of cable resilience lies in calm planning, not last-minute reaction. Seabed routes are now critical infrastructure, like power grids or satellite systems. Leaders who prepare—not just with gear, but with drills, partnerships, and policies—will weather the next test.

China’s new cutter changes the equation. But it also highlights what’s needed most: visibility, readiness, and restraint. The deep sea has become a new frontier—not just of engineering, but of global strategy.

FAQs

What does China’s deep-sea cutter do?

It slices undersea internet cables with high precision at great depth.

Why is the cable cutter a concern?

It can silently disable global data routes without easy detection.

Is the tool only for civilian use?

No, it has dual-use potential for both repair and sabotage.

Can these tools be tracked underwater?

Autonomous subs are hard to track due to stealth and depth.

How can nations protect undersea cables?

With sensors, patrols, rerouting plans, and international coordination.